CNC aluminum welding parts

Custom Qualified Aluminum Welding Parts

CNC parts, CNC precision auto parts, CNC motorcycle parts, CNC machine parts, etc.

Material available: Aluminum: Al6061, Al6063, etc.

Surface treatment available: Zn-Plated, Ni-plated, Passivated, Tin-plated, Sandblast and Anodize, Polish, Electro Painting, Black Anodize, Plain, Chrome plated, Hot Deep Galvanize (H. D. G.) etc.

Contact us now to customize your exclusive welding parts!

A: EXW,FOB,CFR/CIF,ect

A: Yes, we provide OEM services for mass production. Feel free to tell us about your needs.

It is possible to laser etch your logo on the products.

A: We are very flexible with shipping and have dealings with most major courier services around the world. When placing an order, simply provide us a shipping address and contact information, we will handle the rest. If there is a forwarder or courier you prefer to use, just let us know and we will accommodate.

A: We stock many of our standard models. If you would like to test a sample first, we are pleased to send sample to you. If you have special needs, please let us know and we will try our best to send you samples as soon as possible.

A: Please give us the key parameters of the products.Feel free to contact us and give the information, we are very glad to help you if you are confused in selection.

A: Of course. But the drawing or samples of the products should be offered by your company.

A: Delivering quality products is an absolute priority for us. We have test procedures throughout the manufacturing process starting from individual components. If you need a specialized products from us, we also augment our existing test plans with custom testing solutions. In the rare case that an issue does arise, we will work with you to solve any problems in a timely and transparent manner.

A: If you are ordering samples of standard models, we can usually have them shipped and delivered within 15 days by air. When requesting custom products, please allow us a 4-5 week lead-time.

A: Certainly, we can. If you want to replace a products in an existing application,please send us a drawing or sample and we can help you find a suitable replacement. Or, you can contact us and describe your application, our engineers will work together with you to find a solution tailor-made for you.

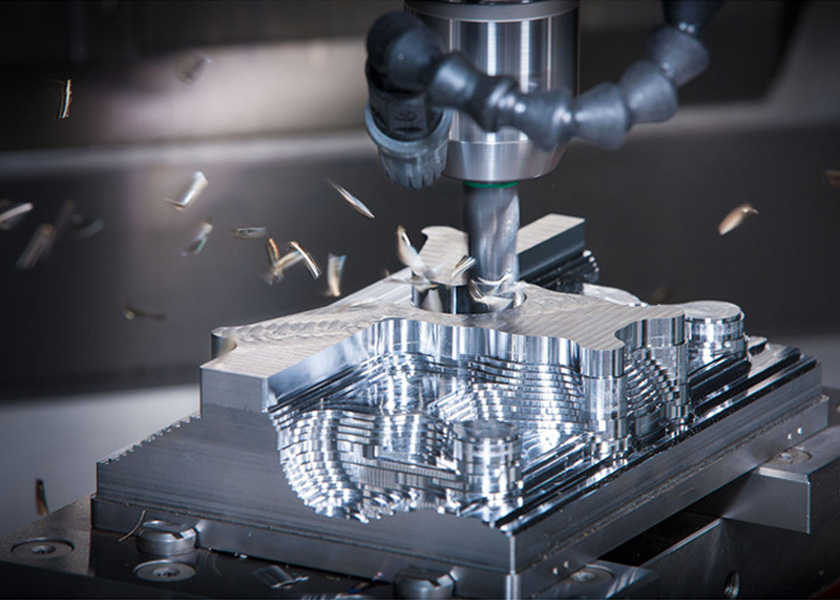

CNC Milling

Our CNC milling process produces custom prototypes and end-use production parts in as fast as 1 day. We use 3-axis milling and 5-axis indexed milling processes to manufacture parts from more than 30 engineering-grade plastics and metals.

We have multiple toolsets based on efficient cutters for a particular plastic or metal material. The machine then rapidly mills parts out of the block in a subtractive manufacturing process that uses either 3- or 5-axis milling.

Machined plastic parts are left as-milled, which typically means they show visible tool marks. Some metal parts allow more finishing choices. When the run is complete and your required surface finish is applied, parts are boxed and shipped shortly thereafter.

Equipment | Quantity |

CNC machining centre | 14(contain 4axis processing centre) |

CNC milling machine | 2 |

CNC lathe | 8 |

Cutting machine | 4 |

Three - Comero | 1 |

Welding machine | 4 |

Punch | 2 |

Blister packaging machine | 1 |

Vibratory Be-burring machine | 2 |

Other machine | 20 |

In order to ensure that the raw materials meet the requirements, in addition to the routine inspection of material brand, heat treatment and standards, the hardness, chemical composition and mechanical properties of the raw materials will also be inspected or sent to a third party for testing.

In order to ensure that the raw materials meet the requirements, in addition to the routine inspection of material brand, heat treatment and standards, the hardness, chemical composition and mechanical properties of the raw materials will also be inspected or sent to a third party for testing.

Prevent fake and shoddy raw materials and standard parts, and conduct traceability inspection on material certificates or COC and physical objects based on lot number / batch number; Ensure the integrity of all chains of material manufacturers, distributors and agents.

Prevent fake and shoddy raw materials and standard parts, and conduct traceability inspection on material certificates or COC and physical objects based on lot number / batch number; Ensure the integrity of all chains of material manufacturers, distributors and agents.

In order to meet the environmental protection requirements, the supplier shall provide relevant COC certificates; Meanwhile, we regularly sends the third party for RoHS and reach tests.

In order to meet the environmental protection requirements, the supplier shall provide relevant COC certificates; Meanwhile, we regularly sends the third party for RoHS and reach tests.

In order to avoid mixing, color identification shall be carried out on the side of aluminum alloy raw materials in the warehouse to achieve visual management.

In order to avoid mixing, color identification shall be carried out on the side of aluminum alloy raw materials in the warehouse to achieve visual management.