Luckyway is specialized in all kinds of custom motorcycle accessories, auto accessories and metal welding accessories. Luckyway is now trading their products worldwide.

Luckyway is a research and development, production, international trade, domestic sales and other integrated high-tech company. Luckyway is the designated manufacturer of many Internationally renowned companies. For example SRT in the U.S.A, TNT bicycles in the U.S.A, Motorsports tools in the UK, TLC bikes in the UK, ULVEDAL in Denmark …

- 2012Established

- 3265Solution

- 1000Partners

- 30Product Sales Country

Luckyway is trading our products to worldwide.

- Quality ControlMore than 10 years of customization experience in European and American countries, and passed ISO 9001 quality management system.

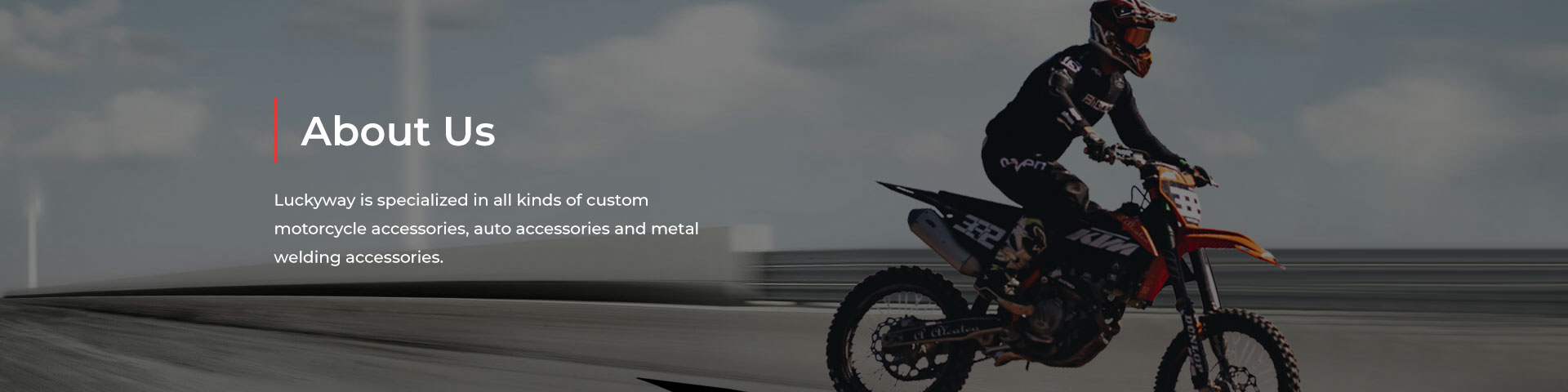

We have a strict quality control system to ensure the quality of each product. Quality control and inspection are carried out side by side with the CNC processing process. - Prompt DeliveryFrom receiving the customized pictures from our customers, our delivery time is controlled within 30 days, also tolerance down to +/-0.0004" (0.01mm).

- Minimum OrderCompared with other companies, our MOQ 50 sets.

We ensure that each set of our products undergoes strict quality inspection before shipment, for your 100% satisfaction.

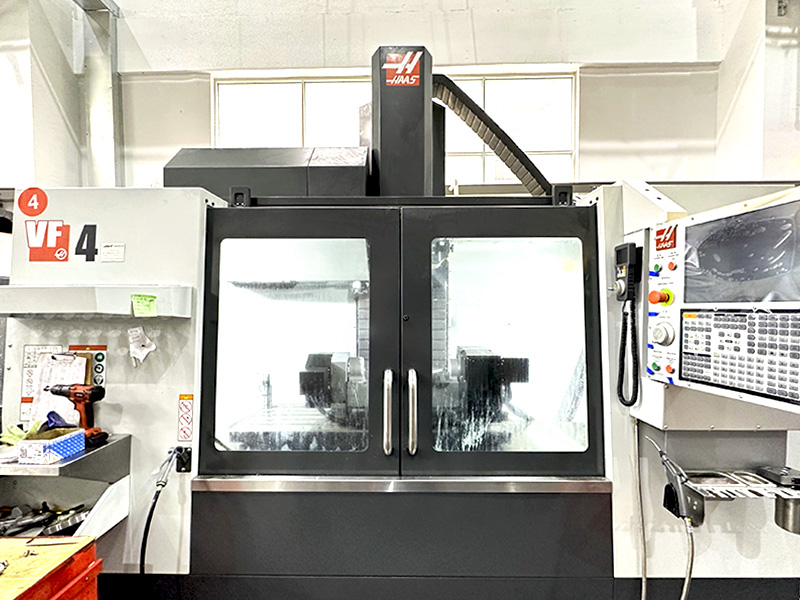

- Certificate of Quality

- As a modern enterprise delicate to designing and manufacturing high-precision machining products, Luckyway has passed ISO9001 quality management system certification, AS9100D aviation quality management system certification, ISO14001 environmental management system certification and a number of NADCAP special process certifications.

Export And Cooperation

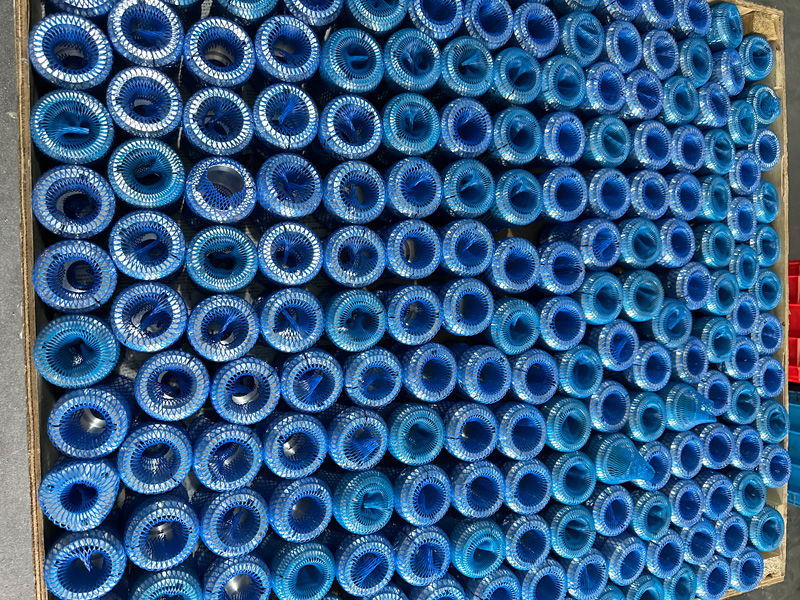

The packaging components is a meticulous process that exemplifies attention to detail. Each individual component is delicately nestled within custom-made, foam-lined compartments, ensuring a snug and secure fit. These components are often encased in anti-static bags to safeguard against electrostatic discharge, and then placed within sturdy, double-walled cardboard boxes. To prevent any potential damage during transit, additional shock-absorbing materials such as bubble wrap or foam inserts are carefully integrated.

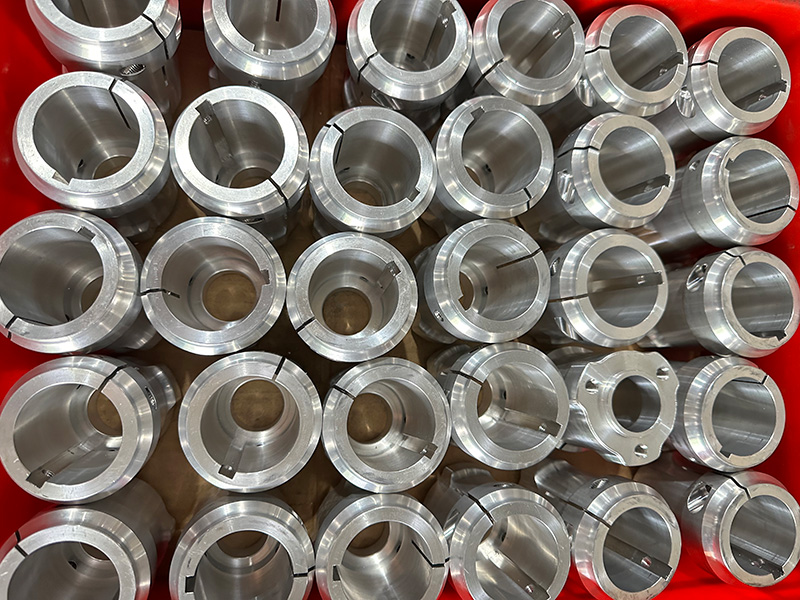

Our manufacturing process upholds stringent quality control standards to ensure the highest level of accuracy and reliability. Every step of production is subject to meticulous inspection, with precision measuring instruments and cutting-edge technology playing a pivotal role in the assessment of each component's specifications.

In-process inspections are conducted at regular intervals, verifying tolerances and dimensions to the finest micrometer. Once a component nears completion, it undergoes a comprehensive quality assessment, where skilled technicians meticulously scrutinize it for any imperfections, surface defects, or deviations from the required specifications.

CN

CN